How to produce a high quality sex toys?

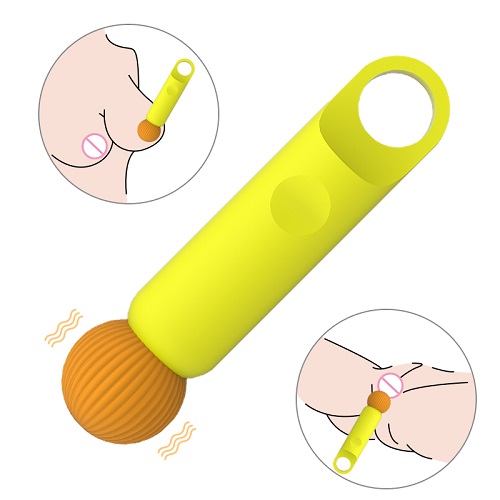

Most adult products have internal mechanisms consisting of three main parts; the battery, motor, and a Printed Circuit Board Assembly (PCBA). The PCBA is basically the computer inside the product that allows it to function.

These components are wrapped in layers of silicone and body-safe ABS material.

Common Complaints

When customers come to us, there are several things they frequently complain about. These elements we pay specific attention to ensure the complaint doesn't persist.

These include:

"Poor product vibration"

"Noisy"

"Obvious part line"

"Weak Bluetooth signal"

.......

3 Components for an Excellent Product

1. Raw Materials

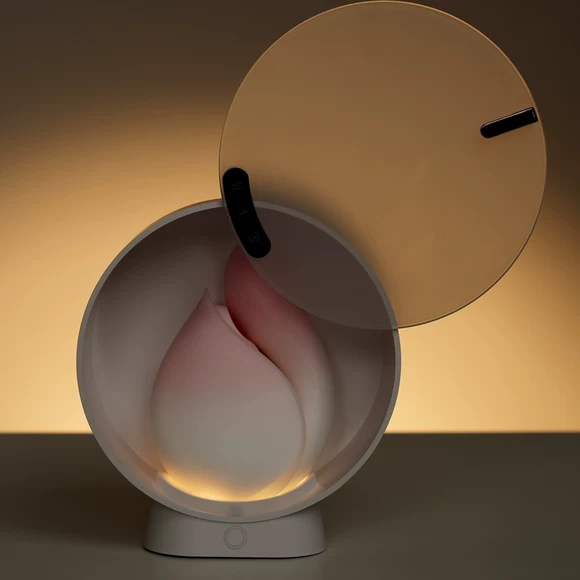

To have a high-quality product, quality must be folded in from the very beginning. The foundation of every high-quality adult product is the raw materials used. Our products use high-quality, body-safe silicone and ABS, guaranteeing the best user experience for your product.

2. Production Process

The first step we take when creating a product is opening the mold. Production begins when the mold is completed. Because of the highly manual aspects of producing adult products, quality control is much more effective, making for higher quality products as a standard.

Take the example of liquid silicon fully encapsulated process, the production process is divided into several steps:

Assembly: Assembling the battery, motor, and PCBA

Glue Wrapping: Lemonpard's factory has the most advanced full glue covering process using liquid platinum silicone and injection molding. Our factory can use any Pantone color you select to create your desired effect.

Grinding: The product is smoothed by a machine first. If imperfections are found after a quality inspection, an experienced master grinder hand polishes the product. This process ensures smooth lines with no mold lines.

Oil Spraying: As a final coat, oil is sprayed to brighten the color and smooth the surface. Choose a metallic color for a shinier, metallic silicone color.

Testing: Confirming the product works correctly.

Charging: Making sure the battery points are working correctly and holding power efficiently.

Packaging: Make sure the product is encased in the protective box which is clearly marked with its information and logo/design.

3. Technology

Bluetooth technology, while very popular and widely used, is often outsourced. Most factories do not have the in-house capability to manufacture Bluetooth products, so customization is not available for these factories.

With the in-house bluetooth team, mantang can create a customized bluetooth experience. For example, we provide a Bluetooth function, which can be connected to a mobile phone, a computer or an electronic watch for one-to-many control.

Our team is actively developing more innovative features, to keep our products state-of-the-art.

Mantang Provides Customized Experiences

We’ve always used the very best materials and put a lot of thought into our toys – to make sure they always take things up a level and never distract you from the fun. What’s more, our sustainable manufacturing facility here use enviormental protection material gives us a really tiny CO2 footprint. This increases brand recognition and loyalty. The high quality of Mantang products improves this. Contact us for more information or technical support.