Your Professional Adult Toys Manufacturer

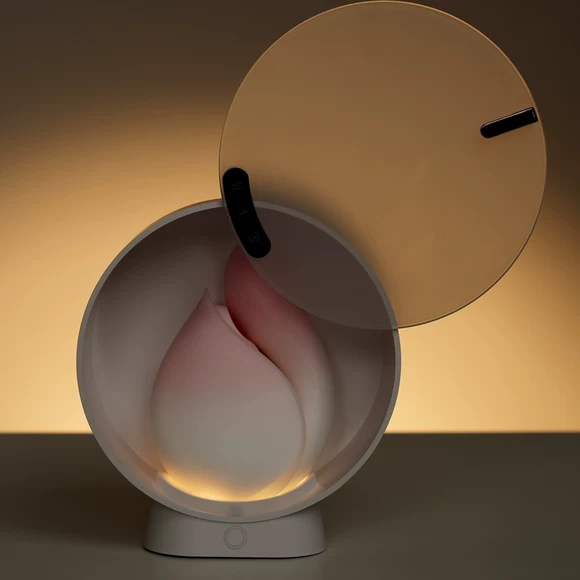

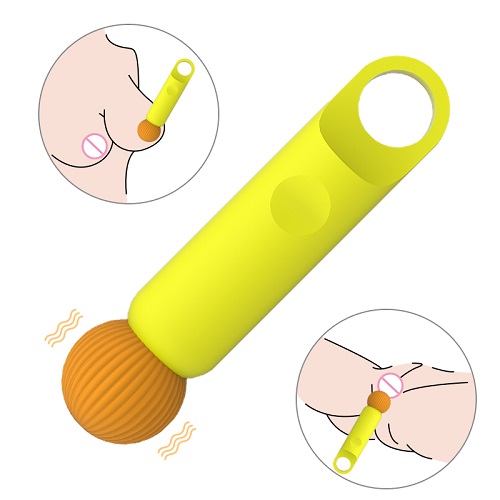

In its quest for appealing products, Mantang has made advancements in the design of its sex toys as exemplified by winning the 2018 China Innovation Design Award. All our products match market demands by utilizing various shapes and forms that appeal to people’s senses.

We possess advanced equipment and full production lines to produce parts that can be quickly assembled. Conducting thorough inspections, we test each adult product according to their qualities.

1.Innovative Design

Free design idea service

We combine your initial product needs with the market trend so that you can get a final product that is appealing to your target audience. Strong designing capability enables us to launch new products at the rate of about 15 pieces per quarter.

Free design modification

We create and deliver a perfect sampling model based on the sketch with your requirements, thus you can touch the product, assess its quality, and see if it is accessible and capable of increasing your sales and brand awareness.

2.Cost-effective Solution

We offer OEM & OEM services to improve sex toys to improve hardness, softness and functions for our toys. Design modifications comply with your requirements.

Quick customizations can allow you to come with your designs that suit your market’s preferences.

Using low-cost production processes, we are able to minimize expenses in refining our sex toys for your audience. Make the most out of our price-friendly solutions to get more sales.

3.NDA Support

As most customers have self-owned product designs for their targeted markets, Mantang as a customer-focused enterprise spares no efforts in strategizing IP protection. We are absolutely in conform to the standards of Non Disclosure Agreement to sustain your business development.

With self-made molds based on customer requirements, Mantang has the capacity to make a prototype of you-required performance, while the peers make sampling with the open molds.

4.Complete Production Line

Our manufacturing includes a wide range of in-house capabilities such as silicone casting, plastic injection, CNC machining, electronics assembling and 3D printing.

Through our full equipment and expert engineers, we are able to come up with parts quickly to meet market demands.

From a supply of plastic, TPE, silica gel and other materials, we carefully craft and assemble them into the ideal sex toys for your audiences to enjoy.

5.Full Quality Inspection

Incoming raw materials inspection

Food grade silicone with certifications like RHOS, REACH, CE and California 65, Phthalate free.

Full inspection of core parts, destructive aging tests on motors and batteries, and life tests on product keys

On-going performance tests

waterproof test, noise test, charge and discharge aging test, wipe test, tensile test, drop test, odor test, etc.

Assembly test

Inspect each product part to ensure function and appearance

Finished product test

Checking product packaging